From Design to Delivery: Your Reliable Lamp Housing Manufacturer in China

- Luke LU

- Apr 6, 2025

- 3 min read

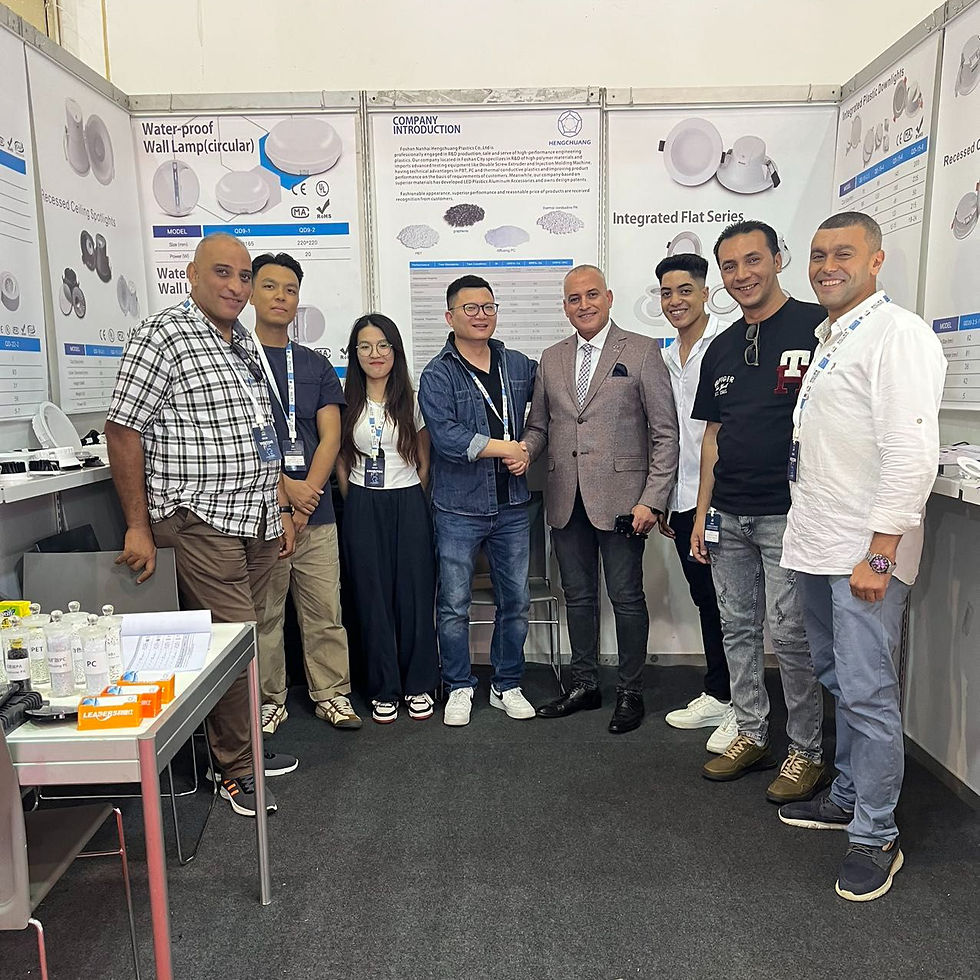

Hello, this is Luke, here to briefly let you know how Hengchuang makes high-quality lamp housing. Throughout the course of my 15-year career, I have watched our trade make great strides, and I am proud to have developed with my peers into a trusted partner to customers all over the world, delivering end-to-end solutions from design to delivery.

Inspiration: The Story Behind The Design

When I first entered the world of lighting housings, I was keenly aware that a great product begins with great design. That's why at Hengchuang, we make sure every little bit matters. Our design approach, be it for a downlight, spotlight, or recessed lamp housing, remains focused on an innate desire to unite form and function.

I run our design discussions personally, and there’s something magical about engineers and designers working together and seeing ideas coalesce into new things. We pitch ideas, the creative thinking base with practical consideration, We evaluate everything—from the thermal performance of our materials to the aesthetics that will complement cutting-edge LED fixtures. This is when the magic starts to happen.

Selecting materials: Top-performance engineering plastics

Engineering plastics expertise is one of the driving forces in our success. I’m really interested in how these fabrics can elevate a very basic product into something special.” The materials used for our lamp housings are high-performance, including thermal conductive PA, PC, and modified plastic.

These materials are lightweight but retain excellent heat transfer, durability, and safety properties. This is why I even often say that by transitioning away from just metal housings to advanced engineering plastics, we’re not only reducing weight — we’re elevating performance and design flexibility. This opens up a broad range of applications for us whilst maintaining competitive ASPs.

Mold Creation and Accuracy Manufacturing

Now, let’s discuss manufacturing—the beating heart of our process. From our design stage, our bespoke mold creation comes into practice. We get a lot of satisfaction out of being able to customize every single mold to exact specifications. We are data driven with research and our impressions in our product delivery. It is this accuracy that ensures a smooth operation of our injection molding process and consistent quality in each lamp housing.

We utilize highly experienced injection molding machines which help convert mass raw material into well-designed lamp housings. It’s a difficult process that’s part art, part science, and I’m astonished at the detail put into every item. Combined with our stringent quality controls, the machines help make sure what we produce matches our high standards, as well as those of our international customers.

A One-Stop Service Experience

What makes Hengchuang stand out as it does is the focus on providing a comprehensive, one-stop service. We do everything under one roof: from material selection from the initial stage through mold development, injection molding, and even your final packaging and delivery of your discrete parts. By using this integrated approach we both streamline our production process as much as possible and make things easier for our customers.

Partner with one trusted source to handle all your lighting housing needs. No need to deal with all the intermediaries and scattered communications — a single step that saves you time, lowers costs, and assures quality. That’s what we work for every day at Hengchuang.

We are looking back at our quality and innovation promise

My years at Hengchuang have taught me that constant innovation is the key to success. We regularly adapt our processes and materials to meet the needs of the changing market. Products will be tested many times and have a number of certificates and certifications.

Our lamp housings are now trusted by customers from North America to Europe and beyond, and I'm proud of them. We take pride in our commitment to quality, innovation, and customer satisfaction in every item we offer.

Looking Ahead

Looking back on our journey — from the light bulb moment in our design studio to the final, polished product delivered into the hands of our customers — I’m excited for what’s to come. As the lighting market develops and we remain dedicated to engineering plastics and new manufacturing processes, I believe Hengchuang will become very important in this transition.

We are not just designing and manufacturing lamp housings; we are developing solutions that light up spaces, complete designs, and connect people to one another. And I urge you to go along on this journey.” Lighting our homes and spaces you use everywhere can feel like a personal project, whether you're a lighting designer, a manufacturer, or just someone who appreciates good quality product — that's when Hengchuang can help.

Another thank you for reading, I look forward to seeing the opportunity to work together and create a brilliant project.

Comments